More News

- Promote Smart Construction And Develop Green Buildings. The Transformation And Upgrading Of The Construction Industry Will Show A New Look.

- zhouxiang 2024catalogue _compressed

- Causes and control methods of welding deformation of steel structures

- How to control laser cutting machine speed in order to increase cutting quality?

- Laser cutting machine need break through the seven key technologies

Electro-slag welding machine

Electroslag welding is one of the main equipment in the box beam welding line, which is a special equipment for electroslag welding of two welding seams between the bulkhead and the bottom plate. Slag welding of box beam bulkheads is divided into two types: cantilever type and gantry type. Wire electroslag welding has high welding efficiency and low cost of use, which is suitable for the production of box beam with large quantity, but the one-time investment cost of the equipment is high.

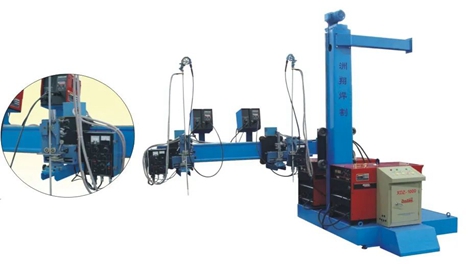

Cantilever electro-slag welding machine

Cantilever wire electroslag welding is mainly composed of walking dolly, column, lifting mechanism, lifting skid, cross arm, dragging plate and other parts, using a special conductive tube, the welding process, the wire is constantly fed into the conductive tube constantly lifting.

Features of fused wire electroslag welding:

1) conductive tube in the welding process to be constantly lifting, electroslag welding part of the structure is complex, the conductive tube itself is also more complex structure, welding power source mostly used in Chengdu Zhenzhong welding machine, making the equipment cost much higher than the fusion nozzle type.

2) The conductive tube does not melt during the welding process, can be used many times, the use of cost reduction.

3) The use of φ1.6mm fine wire welding, the current density of the wire increased, the speed of melting wire to improve the welding efficiency.

Gantry type fused wire electroslag welding

Gantry type slag welding is mainly composed of walking beam, column, upper platform, cross beam, dragging plate, welding arm, cross fine-tuning mechanism and other parts.

The walking beam is composed of walking wheel, axle, motor reducer, etc. Two walking beams constitute a two-wheel drive system, which makes the operation smooth and reliable.

The welding arm is a square tube structure, which is connected to the trailing plate through V-rail. At the lower end of the arm, there is a cross-adjustment mechanism, which is connected to the nozzle clamping device.

Zhouxiang Enterprise

Specializing in the production of H-beam light and heavy steel production line, box beam production line, horizontal production line, double-splicing welding and straightening automatic line, all kinds of automated customized assembly line; including CNC flame plasma cutting machine, fiber laser flat cutting machine, laser pipe cutting machine, tube and plate integrated machine, hand-held laser welding machine, H-beam assembling machine, gantry submerged arc welding machine, H-beam straightening machine, shot blasting machine, H-Beam assembly welding and straightening integrated machine, welding special machine, auxiliary machine, rolling machine, profile bending machine, various welding machines, etc,

Made by Zhouxiang, professional quality, high precision, high speed.

Leading technology, stable quality, products sell well at home and abroad.