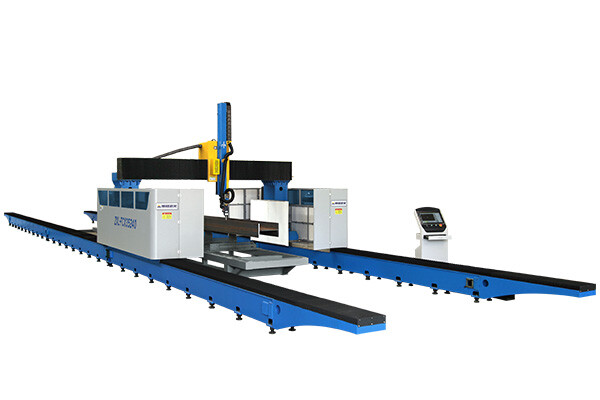

Product Description

The gantry style robot intelligent welding workstation, equipped with an intelligent welding system and a large line scanning stereo camera, can choose between model driven machining (directly importing 3D model files) and non drawing machining (generating point cloud data through workpiece scanning, reverse modeling) to directly match welding process parameters, automatically identify the precise position of the weld seam, and generate the optimal welding process for welding.

1. The equipment is mainly composed of: guide rail parts, gantry parts, robot adjustment parts, electric control box parts, welding power supply parts, etc.

2. The gantry components mainly consist of a driving end frame, a cross beam, an adjusting frame, etc. The driving end beam, cross beam and adjusting frame all adopt box beam welding structure, and then undergo stress relief treatment after welding. The structure is compact and the appearance is beautiful.

3. The active driving end beam of the whole machine uses a Japanese Panasonic AC servo driver and motor to drive a Japanese SHIMPO reducer, and then through a rack and pinion transmission, a horizontal guide wheel is installed on the side of the driving end beam. The guide wheel can be pressed against the guide rail by adjusting its eccentric shaft, thereby ensuring the stability and accuracy of the entire machine operation.

Recommended Products

Leave a Message