Technical Parameter

JW- | 50S | 75S | 89S | 115S | 159S | 245S | 273S |

(mm ) Profile section modulus of bending | 6 | 16 | 30 | 45 | 100 | 320 | 500 |

(MPa) profile yield limit(MPa) | 245 | 245 | 245 | 245 | 245 | 245 | 245 |

Steel pipe | Max section | Φ42×3 | Φ76×4 | Φ89×5 | Φ114×5 | Φ159×5 | Φ245×8 | Φ273×10 |

Min bending Dia | φ500 | φ800 | φ1000 | φ1250 | φ1600 | φ3500 | φ5000 |

Angle steel incurvature | Max section | 45×45×5 | 70×70×8 | 75×75×10 | 100×100×12 | 110×110×14 | 180×180×16 | 200×200×24 |

Min bending Dia | φ700 | φ1100 | φ1200 | φ1300 | φ1600 | φ3600 | φ4200 |

Angle steel excurvature | Max section | 50×50×6 | 75×75×10 | 90×90×10 | 100×100×16 | 120×120×16 | 180×180×16 | 200×200×24 |

Min bending Dia | φ700 | φ1000 | φ1150 | φ1300 | φ1600 | φ3500 | φ42000 |

Channel steel incurvature | Channel steel model | 8 | 14 | 16 | 18 | 22 | 36 | 40 |

Min bending Dia | φ560 | φ800 | φ1000 | φ1350 | φ1500 | φ3500 | φ4000 |

Channel steel excurvature | Channel steel model | 8 | 14 | 16 | 18 | 22 | 36 | 40 |

Min bending Dia | φ500 | φ760 | φ800 | φ1300 | φ1400 | φ3500 | φ4000 |

Flat steel bend in easy way | Max section | 100×18 | 150×25 | 180×25 | 250×30 | 250×40 | 350×60 | 500×75 |

Min bending Dia | φ500 | φ600 | φ900 | φ1000 | φ1200 | φ2400 | φ4800 |

Flat steel bend in hard way | Max section | 50×12 | 75×16 | 90×20 | 100×30 | 120×40 | 190×50 | 200×60 |

Min bending Dia | φ500 | φ600 | φ900 | φ1000 | φ1200 | φ2400 | φ4800 |

Pipe | Max section | φ30 | φ50 | φ65 | φ75 | φ90 | φ145 | φ160 |

Min bending Dia | φ450 | φ600 | φ700 | φ800 | φ1000 | φ1600 | φ1800 |

Standard module Dia (mm) | φ220 | φ350 | φ360 | φ385 | φ460 | φ650 | φ800 |

Bending speed (m/min) | 5.5 | 5 | 5 | 5 | 4.5 | 3 | 3 |

Main motor power (kw) | 3 | 5.5 | 7.5 | 11 | 15 | 30 | 30 |

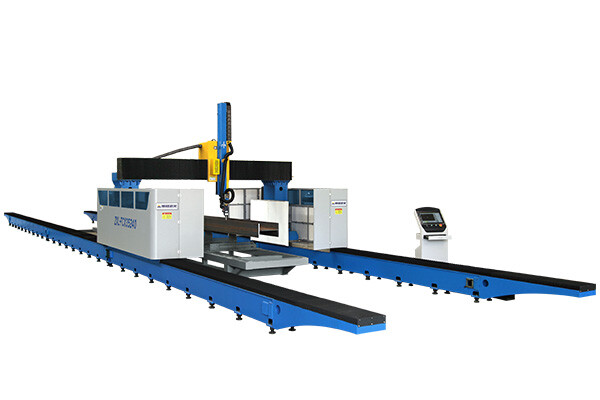

Technical Features

1. Main body of this profile bending machine is steel plate welding structure, annealing post welding to eliminate the internal stress of welding, which can ensure good rigidity and capacity to resist distortion and long time work under full load.

2. This equipment is full hydraulic driving, has the features of compact structure, high reliability and smooth movement.

3. All three roller driving, it can finish prebending and rolling at one time without discharging the workpiece, with high working efficiency.

4. Digital display, the lifting stroke of oil cylinder can be showed directly on the screw of the panel with convenient using and easy operation.

5. Economical and practical, it can finish bending different steel only by changing mould, can be used in wide range.