Product Description

1. This series of welding manipulator has several types for choosing: fixed type, fixed with rotating type, moving with rotating type, etc.

2. The welding manipulator can be 3 in 1 controlled together with welding power, welding rotator or positioner according to users’ requirement.

3. The column and boom adopts welding parts which adopts tempering post welding, then carry out fine machining which can ensure higher precision requirement.

4. Boom adopts square rail, horizontal stretch and retract adopts gear and rack transmission with high precision and stability.

5. There’s safety falling protective device for boom elevating, which can effectively prevent the boom falling problem occurs.

6. There’s cross slider for the welding torch equipped in front of the boom to realize welding torch cross adjust for going up, down, left, right.

7. There’s ladder on the column (heavy duty type), which is convenient for maintenance. Also it is equipped with the platform which is convenient for placing the welders.

8. It can be equipped with wireless remote control box according to users’ requirement, which is convenient for operation.

Our manipulators are developed to upgrade your fabrication throughput, and augment the quality of your weld production. Enhance your automated welding processes for inner, outer, circumferential and longitudinal welding applications with our welding manipulators.We supply machines for a range of manufacturing environments; from pipe fabrication shops to tanker assembly lines, We provide the best manipulator solution to suit your project requirements.

A1: Hard-surfaced rails can withstand enormous pressure.The guide rail surface is not deformed, makes the boom move smoothly, ensuring that the equipment still has high precision and safety after long-term use.

A2: Through the configuration of cross-slider, welding oscillator, welding seam tracker, arc voltage height regulator and other welding devices, high-precision welding seam forming can be realized.

A3: Electrical control adopts imported French Schneider inverter and remote control box operation, motors and control box with IP54 protection against dust and heavy rain.

Customer Case

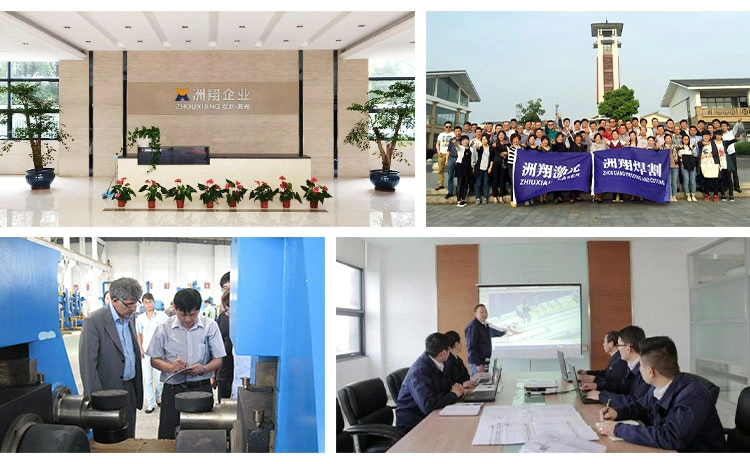

Company Profile

Recommended Products

Leave a Message