1000kg L Type Welding Work Positioner

The L-type three-axis welding positioner makes the workpiece in the best welding or assembly position through the rotation, titling and lifting of the worktable. It can be combined with other welding equipment to form a semi-automatic, full automatic welding machine.

Contact Us

Product Description

Elevating Welding Positioner

The L-type three-axis welding positioner makes the workpiece in the best welding or assembly position through the rotation, titling and lifting of the worktable. It can be combined with other welding equipment to form a semi-automatic, full automatic welding machine.

The L-shaped welding positioner is mainly composed of lifting parts, L-shaped turning parts, rotating parts, conductive devices and electrical control parts.

1.Strong load-bearing capacity

After the positioner’s worktable uses high-strength plates, it carried with heat treatment and finishing after welding. The table rotation adopts slewing support, which has strong load-bearing capacity.

2. Ensure the rail surface is clean and lubricated.

Elevating guide surface through the oil filling oil cup, and a protective cover covering and ensure a clean track surface, to ensure lubrication.

3.Stepless variable frequency speed control

Schneider frequency converter is used to realize variable frequency speed control of worktable slewing and overturning.

Company Profile

Already the first

Is the last one

Recommended Products

Leave a Message

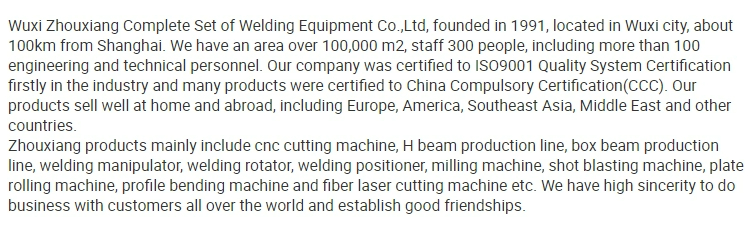

Wuxi Zhouxiang Complete Set of Welding Equipment Co.,Ltd

Industry Garden Donghu,Donggang Town,Wuxi City,Jiangsu,China

+86-510-88794887

yvonne@wxzhouxianghi.com

Get in Touch